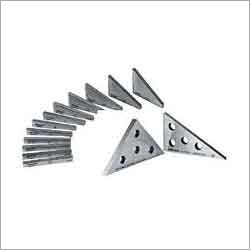

Angle Block

Product Details:

- Equipment Type Angle Block

- Hardness Up to 60 HRC

- Automation Grade Manual

- Resolution 1 (second)

- Features Corrosion resistant, Hardened Steel, Lapped to high precision

- Max Height Up to 100 mm

- Mounting Type Free Stand/Manual Placement

15000.0 INR/Set

X

Angle Block Price And Quantity

- 1 Set

- 15000.0 INR/Set

- Individual or Set of 10/20/30 pieces

- Wooden/Plastic Box

- Rectangular/Trapezoidal as per standard

- Hardened and Precision Ground Steel

- Yes

- Beveled or Sharp as per requirement

- Fine lapped surface

Angle Block Product Specifications

- Up to 100 mm

- Free Stand/Manual Placement

- -10C to 50C

- Manual

- Corrosion resistant, Hardened Steel, Lapped to high precision

- Standard, varies per application

- 1 (second)

- Metrology, Tool Room, Inspection Lab

- Up to 60 HRC

- Angle Block

- Manual

- 650 g

- 1 to 90

- Instant

- Varies - Custom Sizes Available

- Up to 90% (non-condensing)

- 1 to 90

- Precision angle measurement, calibration, inspection

- 2 (seconds)

- Individual or Set of 10/20/30 pieces

- Wooden/Plastic Box

- Rectangular/Trapezoidal as per standard

- Hardened and Precision Ground Steel

- Yes

- Beveled or Sharp as per requirement

- Fine lapped surface

Angle Block Trade Information

- Cash Advance (CA), Telegraphic Transfer (T/T)

- 1000 Set Per Month

- 3 Days

- box

- All India

Product Description

Being a quality-concerned exporter, manufacturer and supplier, we have been resolved to offer an extensive variety of Angle Block. These squares are planned and created utilizing high quality steel so as to achieve finish customer satisfaction. Our array of pieces is accessible in different evaluations, thickness and particulars according to the prerequisites of customers. We deliver these Angle Block in reasonable packaging to guarantee secure transportation. These pieces are reasonable for designing and mechanical applications.

Precision Meets Durability

Each angle block in this collection is engineered from hardened steel, delivering both precision and long-term durability. The fine lapped surface enhances measurement accuracy, while resistance to corrosion ensures the blocks retain their quality even under challenging conditions.

Versatility Across Applications

Suitable for precision angle measurement, calibration, and inspection, these angle blocks meet the needs of metrology labs, tool rooms, and inspection facilities. Custom sizing is available, and blocks cover a full measuring range from 1 to 90, making them adaptable for varied tasks.

Engineered for Reliability and Ease

With accuracy up to 2 seconds and instant response time, these manually-operated angle blocks assure dependable results. Their design supports free-standing or manual placement, with maximum height options up to 100 mm and hardness ratings reaching 60 HRC for trusted performance in demanding settings.

FAQs of Angle Block:

Q: How do I use an angle block for precision measurements?

A: To use the angle block, place it on a flat, stable surface or work piece, ensuring the appropriate angle aligns with your measurement tool, such as a sine bar or protractor. Select either beveled or sharp-edged blocks as per your application to achieve accurate calibration and angle setting.Q: What are the benefits of a hardened, precision ground steel angle block?

A: The hardened and precision ground steel construction provides exceptional accuracy, stability, and resistance to wear, while the fine lapped surface ensures smooth interaction with other measuring tools. Additionally, the corrosion-resistant finish guarantees a long service life even in humid environments.Q: When should I consider using a custom-size angle block?

A: Custom-size angle blocks should be used when your application requires non-standard specimen sizes or unique angles not available in standard sets. This is especially useful in specialized calibration or inspection tasks where precise fit and measurement are crucial.Q: Where are these angle blocks typically employed?

A: Angle blocks are commonly used in metrology laboratories, tool rooms, and inspection labs across industries that demand precise angle measurement and calibration, such as manufacturing, quality control, and research facilities.Q: What is the process for maintaining angle blocks to ensure longevity?

A: Store angle blocks in their provided wooden or plastic boxes to prevent physical damage. After use, wipe them with a clean, dry cloth and, if necessary, apply a light rust inhibitor. Regular calibration checks help ensure continued measurement accuracy.Q: Can these angle blocks function accurately in extreme conditions?

A: Yes, the angle blocks are designed to work efficiently in temperatures ranging from -10C to 50C and humidity levels up to 90% (non-condensing), ensuring consistent performance in a wide variety of working environments.Q: What unique features make these angle blocks suitable for industrial use?

A: These blocks provide instant response, an accuracy of 2 seconds, and options for beveled or sharp edges. Their manual control and robust construction make them ideal for industrial settings, offering reliability for high-precision measurement and calibration needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email